Mggn150r Mggn200r Mggn250L Mggn300r Mggn400

Basic Info.

| Model NO. | MGGN150R |

| Inserts Material | Cemented Carbide |

| Workpiece Material | Steel |

| Insert Types | Mggn Insert |

| Name | Carbide Inserts |

| Transport Package | Plastic Case and Carton |

| Specification | Small |

| Trademark | ESTOOL |

| Origin | Zhuzhou, Hunan, China |

| HS Code | 8208101100 |

| Production Capacity | 50000PCS/Month |

Product Description

MGGN150R MGGN200R MGGN250L MGGN300R MGGN400-R Parting and Grooving Carbide Inserts CNC Lathe Tools Cutting Turning Tools MGGN-L

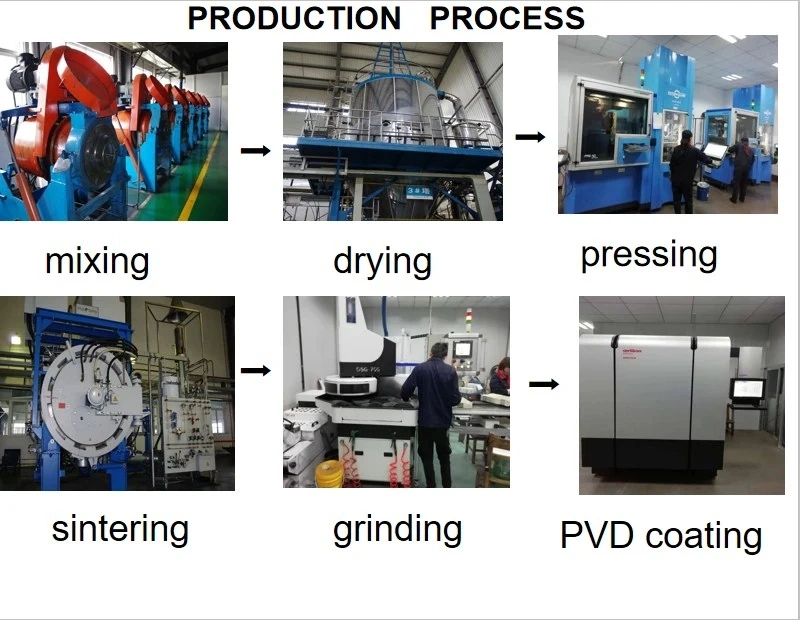

-factory direct sell, with labeling service, wholesale price, sample offered,premium quality, professional technical supportProduct DescriptionParting and grooving inserts are inserts for cylinder parting and grooving, including to the outer circular, the inner hole groove, the cutter withdrawal groove, and the end face groove.The groove shape includes the narrow, wide, and forming groove.MGMN cutting insert is shaped for parting and grooving. Cutting edge shape is straight without hole through insert. Strong cutting edges realize best reliability in hard cutting conditions and long endurance. MGMN is not standard ISO code.

Application:

With our cutting tools for parting and grooving, you get high productivity and long tool life, helping you deliver plenty of components out of the workshop door.Recommended for different purposes and applications in parting and grooving .It performs well on turning material steel, stainless steel and cast iron.

Grades Description:

| CVD coated cemented carbide | ||

| Grade | Description | Equivalent to ISO |

| YC1015 | MT-CVD coated, the substrate with excellent wear resistance in combination with MT-TiCN,fine grained AL2O3TiN multi-layer coating, which is suitable for finishing of steel. | P05-P15 |

| YC1025 | MT-CVD coated, Cutting edge with good toughness in combination with TiCN+Al2O3(thick)+TiN multi-layer coating,which is suitable for semi-finishing of steel. | P10~P25 |

| YC1035 | MT-CVD coated, the substrate with excellent toughness and plastic deformation resistance in combination with TiCN+Al2O3(thick)+TiN multi-layer coating, which is suitable for roughness of steel. | P20-P35 |

| YC1125 | Special strength toughness of the insert substrates,perfect combinations with MT-TiCN,ultra fine AL2O3,coatings ,common grade for steel,suitable for steel,cast iron,stainess steel in semi-finishing,finishing | P10~P25 |

| YC1315 | The combination of high wear-resistant substrate with MT-TiCN,fine grained Al2O3 and TiN coatings,is a ideal grade of finishing processing of steel,stainess steel in the case of hight speed cutting. | P10~P25 |

| YC1325 | With optimized toughness and hardness of the substrate and MT-TiN, fine grain Al2O3 and TiN coating and with a special post-treatment process, the formation of excellent performance of the double-color coating, suitable for steel, stainless steel and cast iron in semi-finishing and finishing | P10~P25 |

| YC1335 | Substrate with high strength and strong resistance to plastic deformation combined with MT-TiCN,fine grained Al2O3 and TiN coating having great toughness,is suitable for light load ronghing of steel,stainess steel and cast iron | P10~P25 |

| YC2105 | MT-CVD coated, the super fine grain size substrate with excellent hardness in combination with Al2O3(extra thick) coating, the smooth surface, which is suitable for turning and milling of grey cast iron at high speed | K05-K15 |

| YC2115 | MT-CVD coated, the substrate with excellent hardness and stripping resistance in combination withAl2O3(thick) coating, the smooth surface of the tools, which is suitable for turning and milling of cast iron at middle and high speed. | K10-K30 |

| YC2215 | High wear-resistant substrate, new generation coating process with perfect combination of MTTI (CN), Super Al2O3, TiCN coating, initial grades of ductile cast iron, forged cast iron, high cutting speed allowance | K10~K30 |

| PVD coated cemented carbide | ||

| Grade | Description | Equivalent to ISO |

| YP3025 | 2-4um TiALN PVDcoated,combinating with ultra fine particles'substrates with high-toughness, suitabe for all materials,stainless steel, steel, cast alloy in finishing,semi-finishing | P10-P25 K15-K30 |

| YP3125 | 2-4um ALCr+ALCrSiN PVDcoated,combinating with ultra fine particles'substrates with high-toughness, suitabe for all materials,stainless steel, steel , cast alloy in finishing,semi-finishing | P10-P25K15-K30M10-M25 |

| YP3225 | 2-4um AlCr + AlCrSiN PVD coating, combined with ultra-fine particle matrix, has high wear resistance, suitable for finishing and semi-finishing of heat-treated steel ,stainless steel and quenched steel | P10-P25K15-K30M10-M25 |

| YP3330 | The latest AlCr + AlCrSin PVD coatings, combined with ultra-fine particle substrates, has high wear resistance and excellent performance in finishing and semi-finishing of stainless and hardened steel | P10-P25K15-K30M10-M25 |

| YR3025 | 2-4um TiALN +TiN PVDcoated,combinating with fine particles'substrates with high-toughness, suitabe for all materials,high-temperature alloy Ti alloy in semi-finishing,roughing | P20-P30K20-K35 |

| YR3025 | Unique material matrix, with 2-4um TiAlN PVD coating, with high toughness and heat resistance, suitable for high temperature alloy, heat resistant alloy and other difficult to process materials finishing, semi-finishing | S10-S25 |

| YR3325 | The latest AlCr + AlCrSin PVD coatings, combined with unique rare metal substrates, offer high wear resistance and excellent performance in finishing and semi-finishing of superalloys and heat resistant alloys | S10-S25 |

Positive round RCMX RCMX3209 MO

1. High impact resistance, excellent adhesion, reduced friction.2. Superior wear protection, temperature and oxidation stability.

3. Provides perfect turning surface of the workpiece .4. Less tool breakage, Long tool life.5. A reliable and secure performance every time.