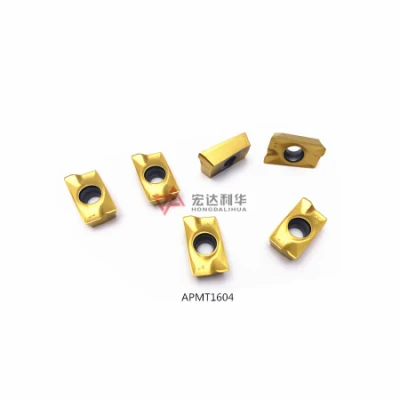

CNC Milling Carbide Inserts Apmt1604 CNC High Feed Face Milling Inserts

Basic Info.

| Business Type | Manufacturer |

| Material | 100% Raw Material |

| Usage | Cutting Steel, Cast Gray Irons, Stainless Steel |

| Advantage | Over 20 Years Experience in This Line |

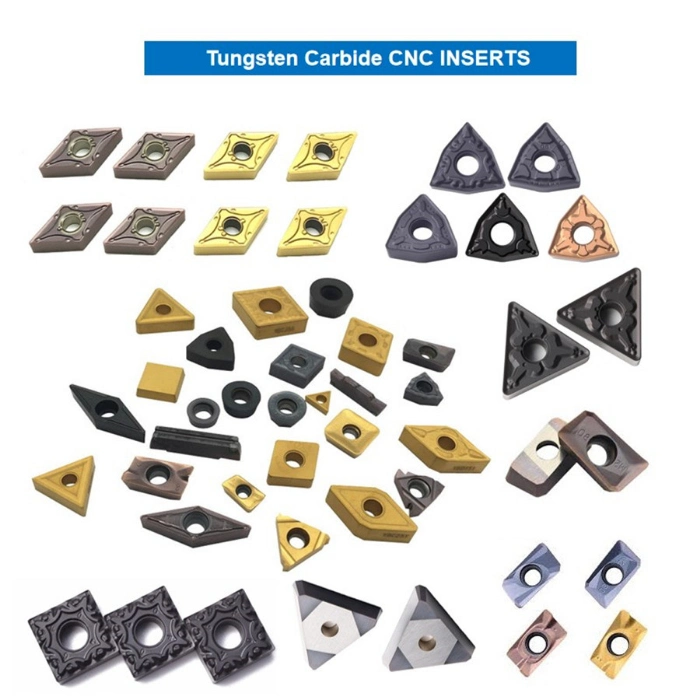

| Name | Customized Carbide Inserts / ISO CNC Inserts |

| Performance | Excellent Wear Resistance |

| Cer | ISO9001 SGS |

| Transport Package | Customized or Standard |

| Specification | ISO9001 SGS |

| Trademark | LIHUA |

| Origin | Zhuzhou, China (Mainland) |

| Production Capacity | 5000kg/Mon |

Product Description

Cnc Milling Carbide inserts APMT1604 CNC High Feed Face Milling InsertsApplications:1.Suitable for Copper, Cast Iron, Carbon steel, Tool steel, Mould steel, Die steel, Stainless steel, Plastic, Arcylic, etc.

2. Applicated for Aerospace, transportation, Medical equipment, military manufacturing, mould development, apparatus and instrument, etc.

Grade Information for non-standard tungsten carbide tool parts

Grade | Density g/cm3 | T.R.S MPa | Hardness HRA | Performance & Application recommended |

YL10.2 | 14.50 | 3400 | 92.5 | Qualified for low speed rough machining,milling,titanium alloy and refractory alloy,espercially for cut-off tool and sick prick. |

YG11C | 14.40 | 2260 | 87.5 | Qualified for molding the drills for heavy-duty rock drill:detachable bits used for deep hole drilling,rock drill torlley etc. |

YG6X | 14.90 | 1560 | 91.0 | Qualified for machiningof chilled cast iron,alloy cast iron,refractory steel ana alloy steel.Also qualified for the machining of common cast iron. |

YS2T | 14.45 | 2800 | 92.5 | Qualified for low speed rough machining,milling,titanium alloy and refractory alloy,espercially for cut-off tool and sick prick. |

YG15 | 14.10 | 2400 | 86.5 | Used for punch dies,stamping dies and wear resistance parts |

Grade | Equal to ISO Category Number | Performance | uses | ||

Density | Bend Strength | Hardness | |||

G/Cm3 | N/mm2 | HRA | |||

YG3 | K01 | 14.9-15.3 | ≥1180 | ≥90.5 | sand-blasting nozzlesQualified for fine turning and half-fine turning when cast iron, non-ferrous metal, alloys as well as non-alloy materials cutting consecutively. Can make wire drawing of steel and non-ferrous metal. Also qualified for sand-blasting nozzles. |

YG3X | K01 | 15.1-15.4 | ≥1300 | ≥91.5 | |

YG6X | K10 | 14.8-15.1 | ≥1560 | ≥91.0 | Qualified for machining of chilled cast iron, alloy cast iron, refractory steel and alloy steel. Also Qualified for the machining of common cast iron. |

YG6A | K10 | 14.7-15.1 | ≥1580 | ≥91.0 | |

YG6 | K20 | 14.7-15.1 | ≥1670 | ≥89.5 | Qualified for finish machining and semi-finish machining for the cast iron, non-ferrous metal, alloy and unalloyed materials. Also qualified for wire drawing for the steel and non-ferrous metal, electric drill for geology use and steel drill etc. |

YG8 | K20-K30 | 14.6-14.9 | ≥1840 | ≥89 | Qualified for rough machining of cast iron, non-ferrous metal, nonmetal materials, drawing of steel, non-ferrous metal and pipes, various drills for geology use, tools for machine manufacture and wearing parts. |

YT15 | P10 | 11.1-11.6 | ≥1180 | ≥91.0 | Qualified for rough machining, semi-finish machining and finish machining during consecutive machining of carbon steel and alloy steel. |

YT14 | P20 | 11.2-11.8 | ≥1270 | ≥90.5 | Qualified for rough machining for rough face of carbon steel and alloy steel, half process during discontinuity cutting. |

YT5 | P30 | 12.5-13.2 | ≥1430 | ≥89.5 | Qualified for rough machining for rough face of carbon steel and alloy steel and discontinuity cutting. |

YW1 | M10 | 12.7-13.5 | ≥1180 | ≥91.5 | Qualified for finishing and semi-finishing machining of refractory steel, high manganese steel and common steel. |

YW2 | M20 | 12.5-13.2 | ≥1350 | ≥90.5 | Qualified for semi-finishing machining of refractory steel, high manganese steel and common steel. |

About Lihua Cemented CarbideEstablished in 1990, specialized in production carbide products more than 20 years and located in zhuzhou city which is the hometown of tungsten carbide in China .Our products sold well to worldwide, has been build a long term relationship with our customers from Italy, Portugal, German, Turkey, USA, Mexico, India, Australia, South Africa etc .Monthly Capacity of 15Ton

We have sophisticated equipments, such as Sintering Furnace, Automatic suppress Machine, Manual Hydraulic Suppress Machine, Ball Mill Machine, Drying Machine, Mixing Machine ect, Our production capacity up to 15 Ton per month. Customized is welcome, customized sample can be ready in 3-5 days and 1 day can deliver for stocks.

Strictly QCWe have a professional QC team follow to the System of ISO9001:2008, Covering the Raw Materials Incoming, Production Processes, Finished Products and Packaging to ensure high quality products output.

Our Exhibitions & Qualifications

Contact:

Foreign Sales Manager : Coco Su

Website: lihuacarbide.en.made-in-china.com

Factory Add: Building B-11,E-commerce Industrial Park ,Xinma South Road ,Tianyuan Zone ,Zhuzhou City ,Hunan Provice ,China 412000