General Turning Inserts for Steel Tnmg Tungsten Carbide CNC Inserts

Basic Info.

| Model NO. | TNMG1604 |

| Type | Cutting Tool |

| Material | Carbide |

| Certification | ISO 9001:2008 |

| Machining Catagory | Finishing, Semi-Finishing, Roughing |

| Shipment | FedEx, DHL, TNT, EMS, UPS, etc. |

| Delivery Time | 7-10 Working Days |

| Application | Metal Cutting Machine |

| Coating | PVD, CVD, Double Coating. |

| Transport Package | Customer Requirements |

| Specification | tnmg series |

| Trademark | RV |

| Origin | Zhuzhou, China |

| HS Code | 8208101100 |

| Production Capacity | 50000pieces/Month |

Packaging & Delivery

Package Size 1.00cm * 1.00cm * 0.50cm Package Gross Weight 0.020kgProduct Description

Description:

The turning tool is the most widely used tool in metal cutting without signature.It can be machined on a lathe outside the circle, end plane, thread, or internal hole, and also can be used for cutting grooves and cutting.On the structure, the tool can be divided into integral tools, welding assembly tools, and mechanical clamping blades.Mechanical clamping blade's turning tool can be divided into machine tool turning tool and indexable turning tool.The cutting performance of mechanical clamping tools is stable, and workers do not have to grind them, so it is applied more and more in modern production.

Picture viewing:

Physical and mechanical properties of grades

RVT1100 | P10~P20 | The special high-hardness substrate of gradient structure, combined with the thick TiCN and thick AL2O3 coating, greatly improves the wear resistance of the inserts. Applicable to steel finishing processing, Stable working conditions, and the pursuit of high wear-resistant occasions. |

| RVT1200 | P15~P30 | The substrate of good toughness and strength combined with the thick TiCN and thick Al2O3 coating makes the coating greatly improved in wear resistance and looks good in appearance. It is suitable for various processing of steel. |

| RVT1300 | P15~P30 | The high-toughness substrate is matched with TiCN and Al2O3 coatings of suitable thickness so that the material can still achieve both wear resistance and stability under strong impact conditions, which is suitable for the rough processing of steel. |

| RVT8100 | P15-P25 M15-M25 | Ultra-fine particle base substrate, high wear resistance, fine edge treatment, suitable for finishing processing and finishing boring of stainless steel. |

| RVT8200 | K15-K25 P15~P25 M15~M25 | The high-toughness substrate is matched with a suitable thickness of AlTiN coating to achieve both wear resistance and toughness. lt is suitable for many fields from general machining of stainless steel turning to mill. |

| RVT8280 | P15-P30 M15-M30 K15-K30 | The preferred grade for stainless turning, for semi-finishing and roughing under continuous, interrupted cutting conditions. |

| RVT8300 | M15-M30 | It is suitable for large depths of cut and large feed of turning of stainless steel under severe working conditions. |

| RVT3150 | K15~K25 | Thick Al2O3 + thick TiCN coating combined with the hard substrate, with advanced coating technology to ensure a smooth coating surface, low friction coefficient, suitable for cast iron finishing processing |

| RVT3260 | K15~K25 | TiN + medium thickness Al2O3 + thick TiCN coating combined with the hard substrate, good resistance to spalling, suitable for continuous and interrupted turning of cast iron with toughness requirements. |

| RVT2100 | K10~K20 | It is suitable for the finishing of aluminum alloy and cast iron. |

| RVT2200 | K15-K25 P15-P25 M15-M25 | It is suitable for various processing of aluminum alloy turning to the mill. |

| RVT6250 | H10~H30 | KT6250 is a PVD nano-coated ultra-fine-grained carbide grade for turning hardened steel. |

| RVT6200 | S15~S30 | The substrate with excellent deformation resistance plus nano-coating, is suitable for the semi-finishing of hard-to-machine materials such as high-temperature alloys. |

| RVC5280 | P10~P25 K10~K25 M10~M25 | The grade for cermet turning, The combination of fine dispersed hard phase particles, binder phase strengthening, and annular phase structure control makes it get good toughness, excellent red hardness, and crater wear resistance and is suitable for the finishing and semi-finishing of steel, cast iron, etc. |

| RVT1330 | P20~P40 | Special Grade for Deburr Turning Inserts |

| RVT3220 | K20-K30 P10~P30 | A tough substrate with TiN+Al2O3+TiCN coating for the general processing of various materials. |

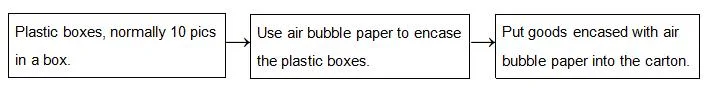

Packaging & Shipping

Company Profile

Zhuzhou Rivictory New Material Co., Ltd, Is located in Zhuzhou, Hunan, which is a Chinese industrial base. The company's main products are tungsten carbide blanks, milling cutters, carbide rods, and epoxy resin insulators, all of which have passed ISO quality certification. At the same time, the company has its own research and development team, which can customize products according to customers' requests.

Production Process

FAQ

1. Who are we?Zhuzhou Rivictory New Material Co., Ltd. is located in Zhuzhou, Hunan, which is China's industrial base. The company's main products are tungsten carbide blanks, milling cutters, carbide rods, HSS drill bits, HSS bar, carbide burrs, CNC inserts, and epoxy resign insulators, all of which have passed ISO quality certification. At the same time, the company has its own research and development team, which can customize products according to customer needs.The company is committed to providing customers with the most suitable products and the best quality services and strives to promote our products to all parts of the world.2. How can we guarantee quality?Always a pre-production sample before mass production;Always final Inspection before shipment;3. What can you buy from us?Tungsten carbide blanks, carbide rods, carbide rotary burrs, milling cutters, HSS drill bits, HSS bars, CNC inserts, and epoxy resign insulators.4. Why should you buy from us not from other suppliers?Our company is located in Zhuzhou city, the capital of non-ferrous metals and high-speed railway. Has a complete industrial chain, design, and research team. Our high-quality products and services are welcomed all over the world.5. What services can we provide?Accepted Delivery Terms: FOB, CIF, EXW, DDP, DDU, Express Delivery;Accepted Payment Currency: USD, EUR, JPY, CAD, AUD, HKD, GBP, CNY;Accepted Payment Type: T/T, Money Gram, Credit Card, PayPal, Western Union, Cash, Escrow.

Need more information about all types of brazed tips, please send us an inquiry.